University of Arkansas staff in the Fay Jones School of Architecture and Design are 3D printing face shields as personal protective equipment for medical and emergency personnel in Northwest Arkansas. They're also collaborating with local design firms, manufacturing companies and alumni on this public health initiative.

How It Started

The 3D printers in the school's Fabrication Labs whir with activity as usual for this time in the spring semester, but this year they're not printing the work of design students preparing their studio project models for end-of-semester reviews.

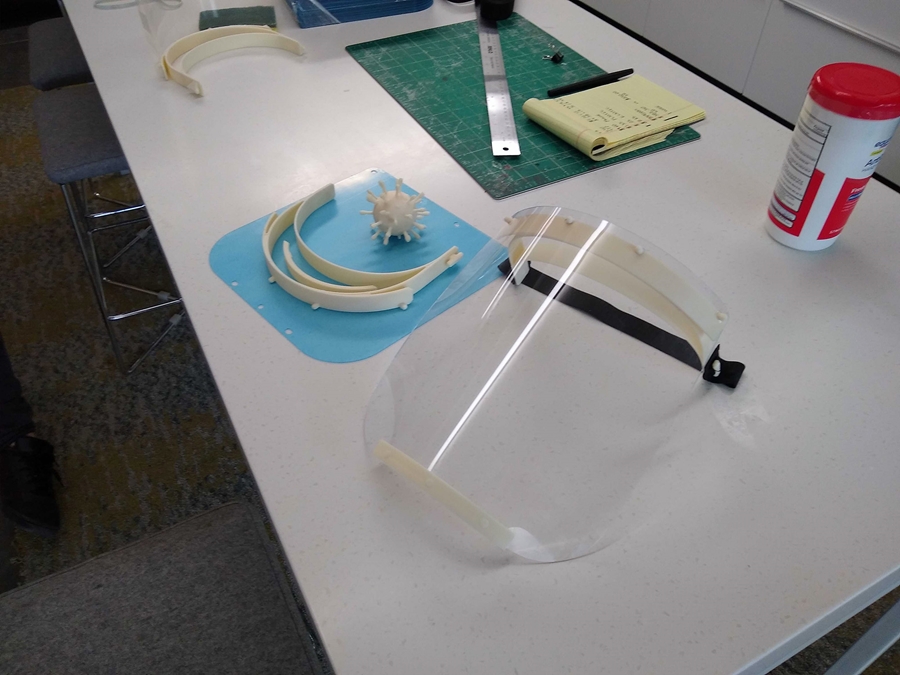

In the wake of the COVID-19 pandemic — with remote instruction and a mostly empty campus — the Fay Jones School staff saw an opportunity to manufacture face shields to help protect healthcare workers against the spread of the coronavirus. The shields help minimize the spread of infection from one person to another by creating a barrier between infectious materials such as viral contaminants and a person's skin, mouth, nose and eyes.

Angela Carpenter, Fabrication Labs manager, and digital fabrication specialist Randal Dickinson are using an open source design for 3D printed face shields from Prusa, a major manufacturer of 3D printers. The shield design allows for eyeglasses and a surgical mask or N95 particulate respirator mask to be worn underneath.

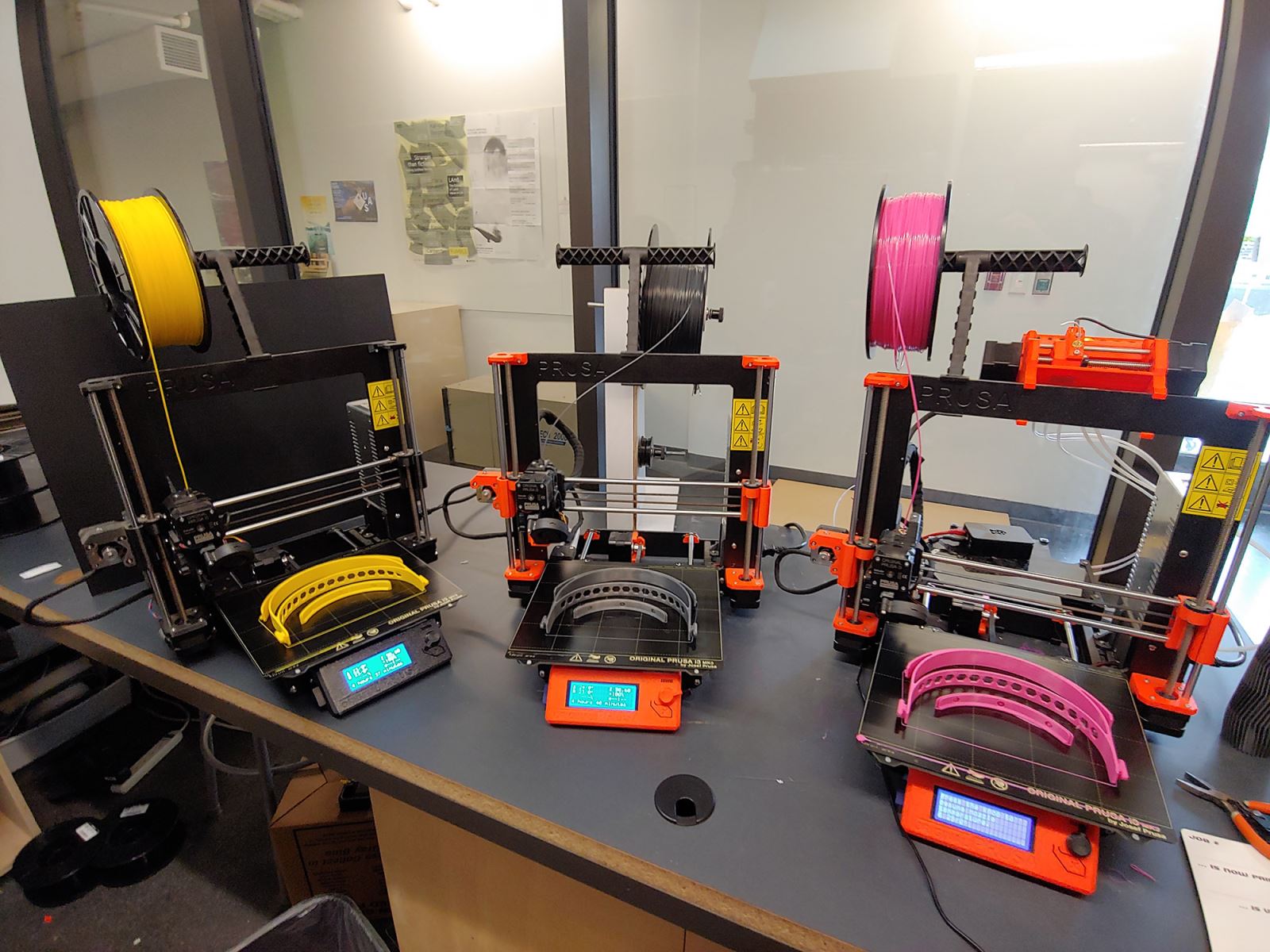

Each frame takes about four hours to complete, and more than 350 frames have been printed since the project began. Dickinson is able to operate seven printers during the day, six of which are located in Vol Walker Hall that he monitors by a web camera.

To 3D print the frames, the staff use PLA — polylactic acid — a plant-based polymer filament, made by Push Plastic in Springdale and purchased at a steep discount. To prepare the clear shield piece, they are using the school's laser cutter to cut the hole patterns in PETG film so that it attaches to the frame. Dare Devil Display Works in Rogers donated the clear film needed to make more than 800 shields.

For their work, Carpenter said they have been in conversation with sculpture faculty in the School of Art and College of Engineering faculty, along with outside industries and design firms.

"I feel like this has allowed for some things to happen that we've wanted to happen, in terms of communicating and understanding who has what tools, and what their capabilities are," said Carpenter, who's also an architecture alumna of the Fay Jones School.

Dickinson said this project makes him feel like they can tangibly contribute something during this unusual time. And it's been good to collaborate with others on campus and outside the school to help the community.

Prusa 3D printers and face shield frames.

Collaborating for community

Carpenter and Dickinson have also begun working with Marlon Blackwell Architects in creating the face shields. The Fayetteville firm is led by Marlon Blackwell, Distinguished Professor and longtime architecture professor in the Fay Jones School. Will Burks, a senior associate at the firm and a Fay Jones School alumnus, said they had also started printing the Prusa design on the firm's new 3D printer to help with the local need. After running low on filament and contacting the Fay Jones School for more, they discovered both teams were printing the same design.

The connection inspired more coordination. Employees at the Blackwell firm are assembling the face shields, then sanitizing and packaging them according to the client's particular needs. In addition, Burks said, centralizing the supply chain by producing the same design will make it easier to replace any damaged or broken clear film pieces.

Through this collaboration so far, the Blackwell firm has delivered 25 face shields to Welcome Health and 50 to Central EMS in Fayetteville. It is preparing another 100 for the Fayetteville Fire Department, which will distribute those to city personnel that need them. In addition, Washington Regional Medical Center has ordered another 300 shields. The team's plan is to 3D print up to 600 face shields in April.

Creating the face shields is a production challenge, rather than a design challenge, Burks said. With their architecture training, though, they have been able to use their sensibilities about materials and locate resources through unconventional sources.

"As architects, we very often have to think on our feet and think and react very quickly to interesting and new problems as they pop up. So, it seems only natural," Burks said.

Modus Studio, another local design firm, has also joined the collaboration. Matt Poe is an associate architect and among several Fay Jones School alumni at the firm. He said that, though this is a different project than they are used to, they have approached it with the same purpose of providing for the health, safety and welfare of their community — just as they do when designing buildings where people work, live and play.

Carpenter said she's been interested to see the national and global community become more open and connected during this pandemic.

"We can log on to a Facebook page and have a conversation instantly with someone around the world about what they're doing. It definitely has been a new experience, and I think one that will stick," she said. "Maybe even help us know how to do things quicker in the future. Don't just sit around and wait, but start asking — just start talking to people."

Read more about how the

U of A is Determined to Help

Topics

Contacts

Michelle Parks, director of communications

Fay Jones School of Architecture and Design

479-575-4704, mparks17@uark.edu