Researchers and industry partners gathered in Fayetteville last month to chart a course for the next generation of batteries, microprocessors and power electronics — including changes that could revolutionize how automobiles, aircraft and spacecraft are designed in a growing electrified fleet.

The workshop was hosted by the Center for Power Optimization of Electro-Thermal Systems, also known as POETS.

Participants included researchers from the University of Arkansas, Stanford University, University of Illinois-Urbana Champaign and Howard University.

The workshop was led by Debbie Senesky, assistant professor of aeronautics and astronautics at Stanford University, and David Huitink, assistant professor of mechanical engineering at the University of Arkansas.

The workshop introduced the questions, "What could be accomplished if the power electronics, microprocessors, and batteries of the future ran hotter (perhaps as high as 500 degrees Celsius, or more)? How would this new operating point revolutionize the design of automobiles, aircraft, and spacecraft?"

The Center for Power Optimization of Electro-Thermal Systems is working to design and develop vehicle electrical systems that are more powerful, efficient and heat-resistant.

The long-term goal is to increase the power density of current mobile electrified systems by 10-100 times over current state-of-the-art systems. Results from the study could save highway vehicles between 100-300 million liters of fuel per year.

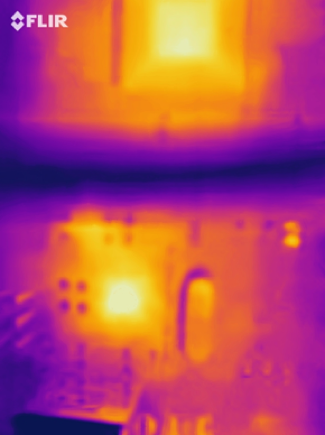

A great challenge in today's semiconductor industry, Huitink said, is the thermal limit of electronic devices — the maximum temperature at which devices can operate.

Increasing that limit would give engineers more options when designing electronics, which could make the final products smaller, cheaper and more efficient at delivering power.

The limit is approximately 250 degrees Celsius (482 Fahrenheit) for commonly used silicon for semiconductors, and often less than 150 Celsius (302 Fahrenheit) for their associated packaging.

That limit prevents the engineering of safe electronic systems with power densities exceeding about 1 kilowatt per centimeter-squared, Huitink said.

To overcome these significant environmental challenges, engineers integrate active cooling systems or complex packaging into the design of electronic modules to make them more durable, but those fixes can significantly increase cost and payload requirements. The workshop was designed to help researchers and businesses address those issues.

"Building on the current successes in POETS and standing upon the shoulders of the 'giants' in power electronics research was the fundamental premise in this workshop," Huitink said. "We have a spectacular team in POETS, through whom we expect to revolutionize the capabilities in mobile power electronic systems. Bringing the key minds in device, packaging, sensing and reliability of these systems together with the major industrial partnerships, ranging from electric vehicles to aircraft and heavy machinery helps us to pinpoint technical challenges, which we can then work together to solve."

About Power Optimization for Electro-Thermal Systems Center: The center is a National Science Foundation Engineering Research Center. At this center, engineering faculty from the University of Arkansas, University of Illinois at Urbana-Champaign, Howard University and Stanford University collaborate with members of industry to identify and carry out research projects to improve the power density of next generation electro-thermal systems that are the most relevant to industry needs.

For more information on high ambient temperature systems, contact David Huitink, dhuitin@uark.edu. For more information on the Power Optimization for Electro-Thermal Systems Centerr, contact Alan Mantooth, deputy director, at mantooth@uark.edu.

Topics

Contacts

Karin Alvarado, marketing and communication specialist

College of Engineering

479-575-4958, karina@uark.edu

Nick DeMoss, director of communications

College of Engineering

479-575-5697, ndemoss@uark.edu