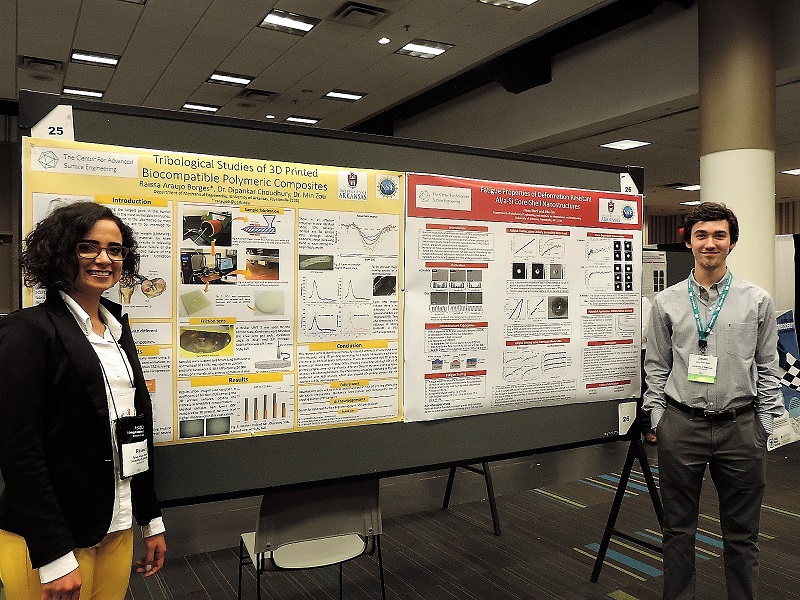

Raissa Borges, a master's degree student in the Department of Mechanical Engineering, and Jason Steck, an undergraduate Mechanical Engineering student, were recognized at the annual meeting of the Society of Tribologists and Lubrication Engineers. Borges received a platinum award at the Student Poster Presentation and Steck received a gold award. Drew Fleming, a doctoral student who is working on the same project as Steck, received a gold award at the 2016 meeting.

All three students are studying under Min Zou, professor of Mechanical Engineering and holder of The Twenty-First Century Professorship in Mechanical Engineering II.

In Borges' poster, titled "Tribological Studies of 3D Printed Biocompatible PCU/UHMWPE Composites," she presented her research on a new approach to making implants to replace damaged menisci in the knee. Most implants of this type are molded out of a solid material, but Borges is testing the use of additive manufacturing, also known as 3D printing, to create these implants. Using additive manufacturing, Borges can create porous, rather than solid, implants, which are closer to the natural structure of the meniscus. These implants can be printed as needed and customized to the person who is receiving the implant.

Her results suggest that implants created through additive manufacturing stand up better to the kind of wear that would experience in the body. She is also researching different types of material in order to create a longer lasting, lower friction and more flexible implant.

Borges explained that she enjoys working on a project that could benefit so many people. "The purpose of this research is what motivates me, because it addresses a problem that is everywhere," she said. "The knee is the most vulnerable joint of the human body."

Fleming has been researching aluminum/amorphous silicon core-shell nanostructures since 2009, when Zou's research group discovered these unique structures. Using advanced nanomechanical characterization tools in Zou's lab, as well as resources available at the U of A High Performance Computing Center, they have been studying the fundamental properties of the core shell nanostructures, which are surprisingly durable and have low frictional properties. Because of these properties, the nanostructures are useful in applications such as microscale devices that have two surfaces that need to slide over each other without causing wear or creating friction.

Fleming explained that this project has given him the rare opportunity to study a completely new material. "What interests me is that it's an opportunity to see through a problem, because this is a new discovery," he said. "It's an opportunity to study very unusual material behavior and understand why it behaves that way."

Steck, who is conducting undergraduate research for his honors thesis, is studying the fatigue properties of these core shell nanostructures using a process called nanoindentation. This involves using a very small diamond tip to indent the surface of the structure and measure the effects. At the poster presentation, Steck presented his research, which shows that the nanostructures don't crack or become deformed during this process, compared to the same materials arranged in a different structure. His poster was titled "Fatigue Study of Deformation Resistant Al/a-Si Core-shell Nanostructures."

Steck explained that the opportunity to conduct research as an undergraduate has given him insight into what he wants to pursue as a graduate student, and he agrees that studying the nanostructures is a valuable experience. "It's nice to work on something new," he said. "Our research is adding to fundamental material science."

Contacts

Camilla Shumaker, director of communications

Engineering

479-575-5697,