FAYETTEVILLE, Ark. – University of Arkansas researchers are part of a team led by the Georgia Institute of Technology that has developed a new approach to space electronics that could change how space vehicles and instruments are designed. The new approach is based on silicon-germanium (SiGe) technology, which can produce electronics that are highly resistant to both extreme temperatures and space radiation.

The $12 million, 63-month project was funded by the National Aeronautics and Space Administration. The 11-member team included academic researchers from Georgia Tech, the University of Arkansas, Auburn University, the University of Maryland, the University of Tennessee and Vanderbilt University. BAE Systems, Boeing Co., IBM Corp., Lynguent Inc. and NASA's Jet Propulsion Laboratory were also involved in the project.

“I have never seen such a diverse team work together so well," said Andrew S. Keys, chief technologist at the Marshall Space Flight Center and NASA program manager.

Alan Mantooth, professor of electrical engineering at the College of Engineering of the University of Arkansas, agreed.

“This was the most successful collaboration that I've been a part of," he said.

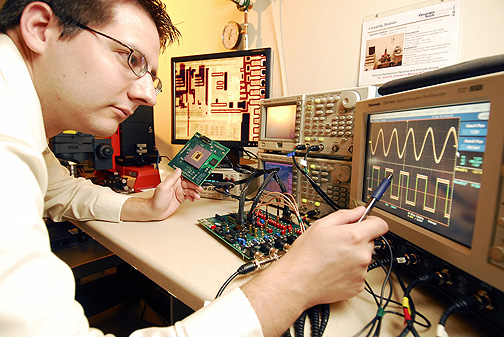

Mantooth led the university research team involved in modeling and circuit-design. He said the extreme-electronics project was great experience for the 82 students who worked on the research at six universities.

"To be working both in analog and digital, miniaturizing, and developing extreme-temperature and radiation tolerance all at the same time – that's not what you'd call the average student design project," said Richard W. Berger, a BAE Systems senior systems architect who collaborated on the project.

There are more research possibilities in the immediate future, as well, according to Mantooth. He and other team members are working with companies such as BAE Systems and other historical NASA contracting companies to develop applications based on the SiGe electronics technologies.

“These projects could involve faculty and students in design, CAD, modeling and packaging projects at the various institutions,” Mantooth said.

The goal of the team was to develop everything NASA needed to design and build extreme-environment electronics for space missions. John Cressler, a Ken Byers Professor in Georgia Tech's School of Electrical and Computer Engineering, served as principal investigator and overall team leader for the project.

“Our team used a mature silicon-germanium technology – IBM's 0.5 micron SiGe technology – that was not intended to withstand deep-space conditions," Cressler said. “Without changing the composition of the underlying silicon-germanium transistors, we leveraged SiGe's natural merits to develop new circuit designs – as well as new approaches to packaging the final circuits – to produce an electronic system that could reliably withstand the extreme conditions of space."

SiGe alloys combine silicon, the most common microchip material, with germanium at nanoscale dimensions. The result is a material that offers important gains in toughness, speed and flexibility. Those qualities are essential to SiGe’s ability to function in space without bulky radiation shields or large, power-hungry temperature control devices. Compared to conventional approaches, SiGe electronics can provide major reductions in weight, size, complexity, power and cost, as well as increased reliability and adaptability.

At the end of the project, the researchers supplied NASA with a suite of modeling tools, circuit designs, packaging technologies and system/subsystem designs, along with guidelines for qualifying those parts for use in space. In addition, the team furnished NASA with a functional prototype –an SiGe remote electronics unit 16-channel general-purpose sensor interface. The device was fabricated using SiGe microchips and has been tested successfully in simulated space environments. The project has moved the task of understanding and modeling SiGe technology to a point where NASA engineers can start using it on actual vehicle designs.

"The silicon-germanium extreme environments team was very successful in doing what it set out to do," Keys said. "They advanced the state-of-the-art in analog silicon-germanium technology for space use – a crucial step in developing a new paradigm leading to lighter weight and more capable space vehicle designs."

Keys explained that, at best, most electronics conform to military specifications, meaning they function across a temperature range of minus-55 degrees Celsius to plus-125 degrees Celsius. But electronics in deep space are typically exposed to far greater temperature ranges, as well as to damaging radiation. The moon's surface, for example ranges between plus-120 Celsius during the lunar day to minus-180 Celsius at night.

The SiGe electronics developed by the extreme environments team has been shown to function reliably throughout that entire plus-120 to minus-180 Celsius range. It is also highly resistant or immune to various types of radiation.

The conventional approach to protecting space electronics, developed in the 1960s, involves bulky metal boxes that shield devices from radiation and temperature extremes, Keys explained. Designers must place most electronics in a protected, temperature-controlled central location and then connect them via long and heavy cables to sensors or other external devices.

By eliminating the need for most shielding and special cables, SiGe technology helps reduce the single biggest problem in space launches: weight. Moreover, SiGe circuits can be placed wherever designers want them, which helps eliminate data errors caused by impedance variations in lengthy wiring schemes.

"For instance, the Mars Exploration Rovers, which are no bigger than a golf cart, use several kilometers of cable that lead into a warm box," Keys said. "If we can move most of those electronics out to where the sensors are on the robot's extremities, that will reduce cabling, weight, complexity and energy use significantly."

The remote electronics unit sensor interface prototype developed by the research team was based on an earlier system that used an assortment of sizeable analog parts for the signal receiving section, with that section supported by a digital microprocessor, memory chips and an optical bus interface, all housed in a protective five-pound box. The new prototype is a miniaturized SiGe sensor interface that weighs about 200 grams and requires no temperature or radiation shielding. Large numbers of these lightweight units could be mounted on spacecraft or data-gathering devices close to sensors, reducing size, weight and power needs while increasing reliability.

NASA currently rates the new SiGe electronics at a technology readiness level of six, which means the circuits have been integrated into a subsystem and tested in a relevant environment. The next step, level seven, involves integrating the SiGe circuits into a vehicle for space flight testing. At level eight, a new technology is mature enough to be integrated into a full mission vehicle, and at level nine the technology is used by missions on a regular basis.

Several space-oriented companies are interested in pursuing the new SiGe technology, Cressler said. NASA, he added, wants the intellectual-property barriers to the technology to be low so that it can be used widely.

"The idea is to make this infrastructure available to all interested parties," Cressler said. "That way it could be used for any electronics assembly – an instrument, a spacecraft, an orbital platform, lunar-surface applications, Titan missions – wherever it can be helpful. In fact, the process of defining such a NASA mission-insertion roadmap is currently in progress.”

A paper on the project findings will appear in December in IEEE Transactions on Device and Materials Reliability, 2010. During the past five years, work done under the project has resulted in some 125 peer-reviewed publications.

Contacts

Alan Mantooth, professor

Electrical Engineering

479-575-4838,

Steve Voorhies, manager of media relations

University Relations

479-575-3583,